This section outlines a few special tools that I feel were designed to make life easier. Some are specialty tools with one specific purpose and others are pretty basic. I’ll be adding to this list as time goes and I pick up new tools.

Brake Bleeding Tool:

This is a multi-purpose vacuum tool. The tool comes in a kit with several different fittings and attachments to do just about anything requiring a vacuum. My only need for this tool, was the brake bleeding function. The process of bleeding the brakes involves relatively simple. Assemble the bleeder by attaching the tubing, catch can and small adapter (see picture below). With the pump assembled, attach the hose to the bleeder, open the bleeder, and squeeze the pump. It’s a good idea to keep an eye on the reservoir to make sure it doesn’t run dry.

This is a multi-purpose vacuum tool. The tool comes in a kit with several different fittings and attachments to do just about anything requiring a vacuum. My only need for this tool, was the brake bleeding function. The process of bleeding the brakes involves relatively simple. Assemble the bleeder by attaching the tubing, catch can and small adapter (see picture below). With the pump assembled, attach the hose to the bleeder, open the bleeder, and squeeze the pump. It’s a good idea to keep an eye on the reservoir to make sure it doesn’t run dry.

One small problem is that the tool will draw air around the threads of the bleeder. If you can’t seem to get a good bleed on the line, or if there seems to be more air than oil coming through, you’ll need to remove the bleeder, wrap the threads in Teflon tape and try again.

As handy as this may seem, using speed bleeders (I realize people have had varying success with these) or the pump-pump-release method tend to be more effective. I honestly believe that it takes high fluid velocity through the system to effectively dislodge all of the air that may be trapped.

Note: This tool can also be used to bleed hydraulic clutch lines.

Honda’s 2-piece valve adjusting tool:

Adjusting valves on any engine can be a hassle…especially on Honda VTEC B-block engines. The purpose of this tool is to make the job of adjusting the valves easier by allowing you to adjust, then tighten the valve lash of the rocker arm.

Adjusting valves on any engine can be a hassle…especially on Honda VTEC B-block engines. The purpose of this tool is to make the job of adjusting the valves easier by allowing you to adjust, then tighten the valve lash of the rocker arm.

The larger of the two pieces fits over the bolt head on the rocker arm. Then, the smaller piece slides through the larger and is used to set the lash. While holding the smaller piece steady, you can tighten the bolt that retains the setting.

I’ve outlined the use of this tool here.

Honda’s Clutch Centering Tool:

Specifically, this is the B-block’s clutch centering tool. At the time, I did not know of a cheaper alternative to this factory clutch centering tool. It is a very heavy, well made tool that could probably handed down generation to generation…given the amount of use that it will see. A bit pricey, but definitely a fine piece.

Specifically, this is the B-block’s clutch centering tool. At the time, I did not know of a cheaper alternative to this factory clutch centering tool. It is a very heavy, well made tool that could probably handed down generation to generation…given the amount of use that it will see. A bit pricey, but definitely a fine piece.

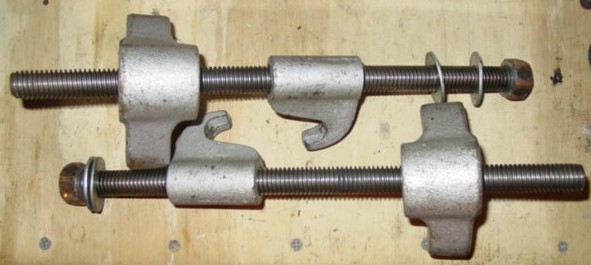

Ball Joint Popping Tool (Pittman arm puller):

Back in the old days, I used to use a pry bar and a hammer to try and pop ball joints. This tool makes the process much easier and significantly safer. The tool slips over the arm or knuckle and the threaded shaft pressed the ball joint out of the control arm or knuckle in which it is attached. This tool is an astounding $20 at AutoZone.

Back in the old days, I used to use a pry bar and a hammer to try and pop ball joints. This tool makes the process much easier and significantly safer. The tool slips over the arm or knuckle and the threaded shaft pressed the ball joint out of the control arm or knuckle in which it is attached. This tool is an astounding $20 at AutoZone.

As useful as this tool has been, I’ve found the pickle fork to be more effective. The pickle fork will rip the ball joint dust boot. Since boots are relatively inexpensive, have extras ready.

Impact Driver:

This tool has very limited use, but when you need it, it makes all the difference in the world. It helps in a situation when a normal screwdriver will do nothing but strip the head of the screw. Using this tool is very easy. Determine which bit fits the screw head the best and hammer away. Place bit in the offending screw, and hit the end of the impact driver while twisting in the necessary direction. This seemingly priceless tool is about $25 at Sears.

This tool has very limited use, but when you need it, it makes all the difference in the world. It helps in a situation when a normal screwdriver will do nothing but strip the head of the screw. Using this tool is very easy. Determine which bit fits the screw head the best and hammer away. Place bit in the offending screw, and hit the end of the impact driver while twisting in the necessary direction. This seemingly priceless tool is about $25 at Sears.

Spring Compressor:

This isn’t the safest way to compress a spring, but it is the cheapest way. It is most effective when used with an impact gun (although not recommended). Place the compressor on either side of the springs and alternate tightening the screws until you can do the work you need to do. It’s a good idea to spray some lube on the threads to protect the tool. This tool is $40.00 at AutoZone.

This isn’t the safest way to compress a spring, but it is the cheapest way. It is most effective when used with an impact gun (although not recommended). Place the compressor on either side of the springs and alternate tightening the screws until you can do the work you need to do. It’s a good idea to spray some lube on the threads to protect the tool. This tool is $40.00 at AutoZone.

Pipe Wrench:

Why do I have a pipe wrench listed? This tool is most helpful for the removal of a stubborn crank pulley bolt. When an impact driver is not enough, the use of this tool and a big pipe is going to work every time. Using this tool is very simple. Wrap the chain around the pulley and use the hook on the handle to attach the chain. Then use a normal wrench on the offending bolt. Apply plenty of pressure and watch your knuckles!

Why do I have a pipe wrench listed? This tool is most helpful for the removal of a stubborn crank pulley bolt. When an impact driver is not enough, the use of this tool and a big pipe is going to work every time. Using this tool is very simple. Wrap the chain around the pulley and use the hook on the handle to attach the chain. Then use a normal wrench on the offending bolt. Apply plenty of pressure and watch your knuckles!

The Big Pipe:

Who doesn’t need a big pipe in the tool kit? No one should be without this tool. Acting to increase the lever arm on any other tool, this tool can help loosen stubborn bolts. A 1-1.5″ steel tube approximate 2′ long will be more than enough. The pipe pictured happens to be an old jack handle.

Who doesn’t need a big pipe in the tool kit? No one should be without this tool. Acting to increase the lever arm on any other tool, this tool can help loosen stubborn bolts. A 1-1.5″ steel tube approximate 2′ long will be more than enough. The pipe pictured happens to be an old jack handle.

A disclaimer to the use of this tool: Tools are designed to withstand a maximum torque load typically as much as a human can produce. By throwing a pipe on the end of a socket wrench, or box wrench, you can very quickly overcome and shatter the tool. I tend to use this tool in a situation where I can’t reach a wrench in a way to apply any useful torque.