The e-brake conversion can be the most difficult element of the entire brake swap and requires more time and research to try and figure out the best solution. At the time of my swap, the only known option for S14’s was to splice the cables. Since then the S-chassis community has learned a few new tricks. I have outlined the most common solutions below.

Over the years, I’ve had quite a few people provide me with useful information that has made this page much more valuable than I would ever have hoped. The following, in one way or another, made contributions to the e-brake section:

- Bart T. aka Hijacker from NICOclub

- Kenny W.

- TN from Nissansilvia.com

- Carmo from NICOclub

- Bobby

- cvc9216 from Zilvia

- cdlong from Freshalloy

Here’s what I have.

Parts Necessary

- Complete e-brake hardware, hub and splash shield

- Refer to my part numbers page for model year variations

- Cables

- For Splice: Z32 + Original 240SX

- S14 no splice: R33 GT-S

- S13 no splice: Z32 2+2 plus mounting bracket (more on this below)

- Du-Bro #244 1/4″ Coated Brass Collars (at least 6)

- 8-32 Bolts approximately 1/2-3/4 long. Hex head preferred.

- 0.5″ insulated clamps, Summit Racing part number: SUM-G1882

Tools Necessary

- Dremel tool w/ cutoff wheel

- Tap and drill 6mm x 1.00

- Locking Clamps (Vise Grips)

- Socket set

- Combination wrenches (box wrenches)

S13 No Splice

Long, long ago, we learned from Dave Coleman of Sport Compact Car fame that Z32 2+2 cables can reach the t-bar by rerouting them through the sub-frame. I can’t remember how he supported the front part of the cables however, many sources have confirmed that you still need a small bracket to secure the cable to the underside of the body. I found the picture below from NICOclub. I’m not sure if the original poster is still making these brackets. I did find similar examples of these on ebay.

S14/S15 No Splice

The R33 Solution. The Z32 2+2 cables work for the S13 however there is no way to make them work on S14’s. A few years after I finished my swap, the resourceful folks of the internet figured out that the R33 Skyline GT-S cables were a direct fit for the S14/S15 chassis. No modifications necessary. I only wish I had known about this before I went through the trouble of building my own! TN from Nissansilvia.com outlined the swap on his S15 and explained the cable installation in the picture below.

Search for “Buy R33 E-Brake Cables” and you’ll find what you need.

Splice

When I originally performed the swap in 2002, my idea was to splice the cables. There is one issue that is difficult to resolve. The cable needs to be supported on either end. If you look at the original setup, you will see that it is bolted to the body in the front and bolted to the caliper on the other. This is difficult to duplicate when you do a splice.

If you’re willing to give it a shot, read on!

The best place for the splice is about 6″ away from the brake hub. I had originally tried to do the splice close to the t-bar. Under the car, here is no way to properly support the cables without creating a bracket. Not happy with that splice, I picked up another set of cables and worked on the splice outlined below.

I used a combination of stock 240SX cables and stock Z32 300ZX cables. 2+2 cables are longer, but still not long enough for S14’s. Since you will be cutting the cables, it does not matter which you use.

In order to support the cables, you will need to use .5″ insulated clamps, Summit Racing part number: SUM-G1882. The sub frame already has a drilled and tapped hole that you will need to use to mount the cable. Since I had the sub frame out, I added a second pair of holes using a drill and tap. The tap size is 6mm x 1.00. The second pair of clams is not necessary.

When installing the clamps and forward portion of the cables, do not completely tighten the clamps. You will need to adjust the length of the cables (especially if you have removed the sub frame).

Attach the cables to the t-bar. Install the sub frame (if you’ve removed it). Once everything is back in, you will need to tighten the clamps. The length of the cables and where you attach the clamps is more of a matter of feel than an exact measurement. You’ll be able to tell once you get in there.

This is the hardest part. I had to go through this process twice before I really had the tension correct. You will need a few locking pliers, or Vise Grips, to do this. You have to get as much slack out of the cables as you can, then hold it while you do the splice.

I want to add this again, slip on the rubber boots before you slip on the clamps!

At the end of the day, I’m glad to see that there is a solution for a functioning e-brake. Whichever you decide to use, know that it’s been done before. The next sections will cover the master cylinder swap. Click the link below for the complete series.

The Definitive 300ZX Brake Swap Series

BUT WAIT! There’s more:

Dual Caliper Conversion!

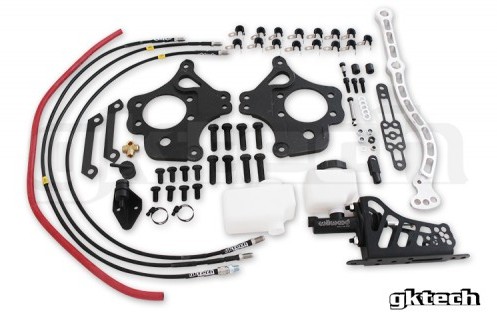

While looking for sources of conversion parts, I stumbled upon a couple of unique solution for the e-brake. For normal use, the drum brake will do a fine job of keeping your car from moving. If you plan on drifting, you may need something more aggressive. Check out these kits below.